Technology Description

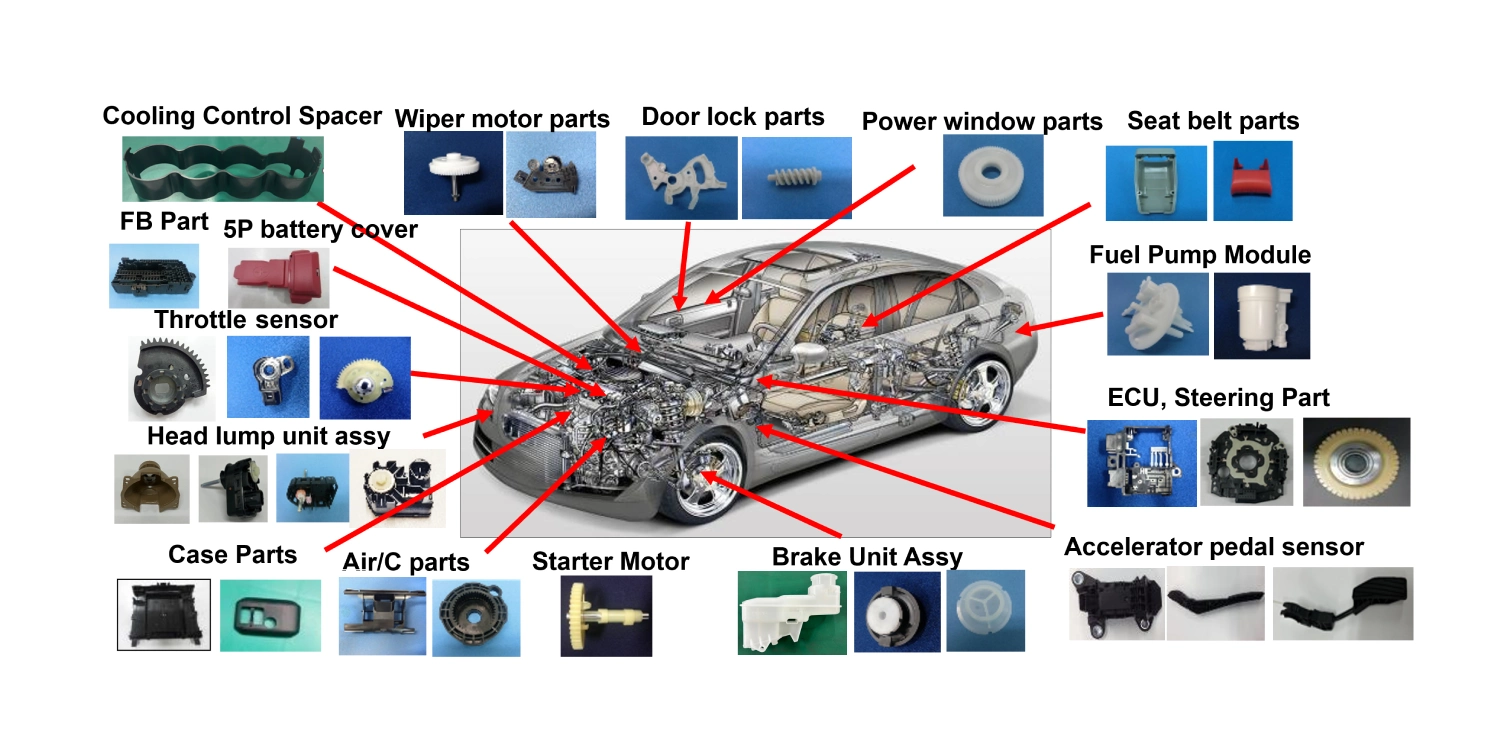

Precision moulded parts play a vital role in modern automotive design and manufacturing. Their ability to deliver high performance while remaining cost-effective makes them the preferred choice for vehicle manufacturers globally. As automotive technology continues to evolve, the demand for innovative and efficient moulding solutions will only increase—driving the future of mobility.

Battery Cover

Battery Cover

Engine Cooling parts

Engine Cooling parts

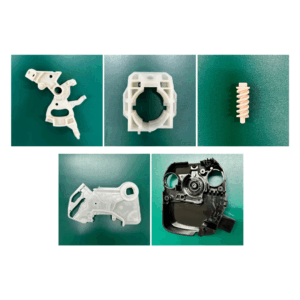

Wiper Motor Part

Wiper Motor Part

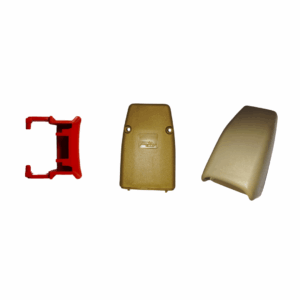

Door Lock Parts

Door Lock Parts

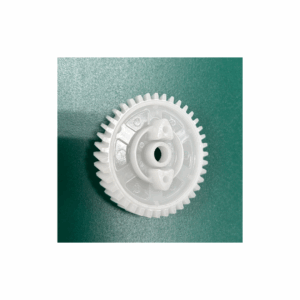

Power Window Part

Power Window Part

Seat Belt Parts

Seat Belt Parts

Fuel System Parts

Fuel System Parts

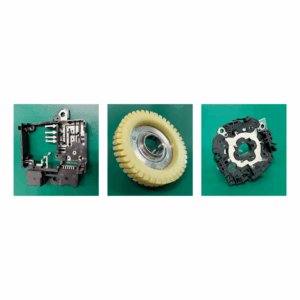

Steering Parts

Steering Parts

Accelerator Pedal System Parts

Accelerator Pedal System Parts

Brake System Parts

Brake System Parts

AC Unit Parts

AC Unit Parts

ECU Parts

ECU Parts

Vehicle headlight Parts

Vehicle headlight Parts

Throttle Sensor

Throttle Sensor

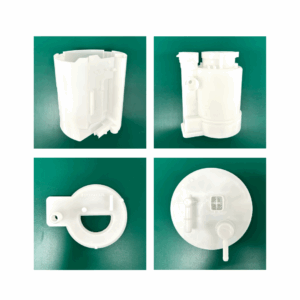

Fuel Pump Parts

Fuel Pump Parts

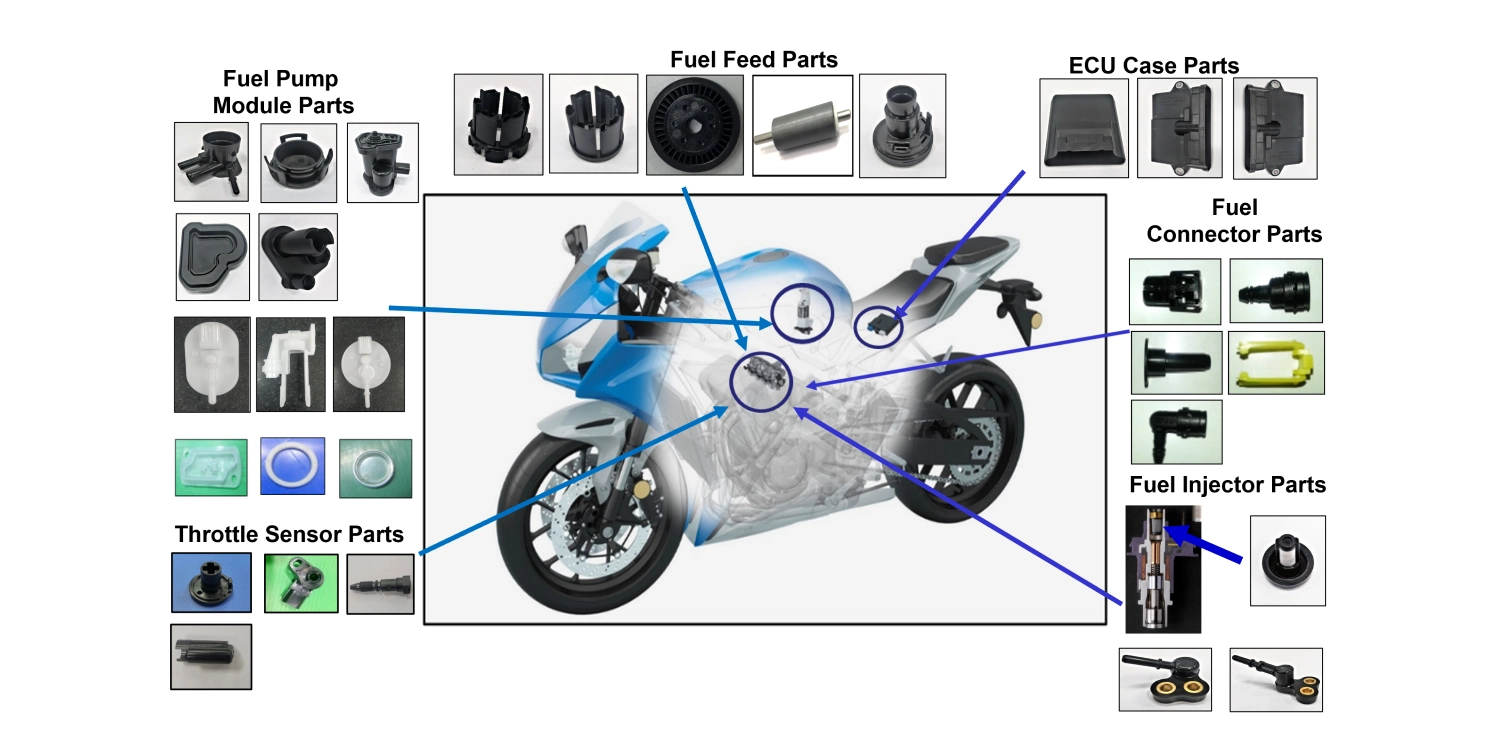

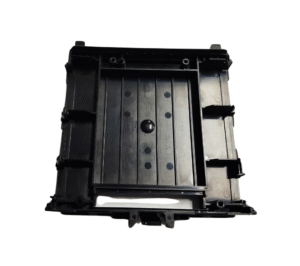

ECU Case Parts

ECU Case Parts

Fuel Connector Parts

Fuel Connector Parts

Fuel Injector Parts

Fuel Injector Parts

Throttle Sensor Parts

Throttle Sensor Parts

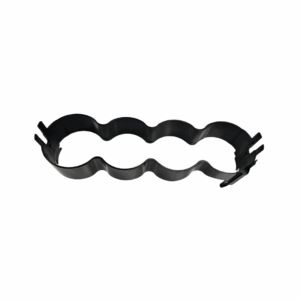

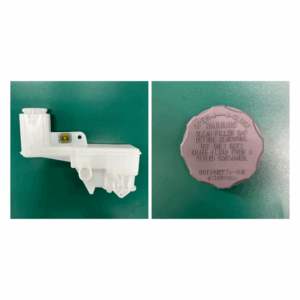

Fuel Feed Parts

Fuel Feed Parts

Advantages of Precision Moulding Parts in Automotive Manufacturing

- High Dimensional Accuracy – Ensures tight tolerances and perfect fitment.

- Lightweight Construction – Reduces vehicle weight, improving fuel efficiency.

- Superior Durability – Resistant to heat, chemicals, and mechanical stress.

- Cost-Effective Production – Allows for mass production at lower costs compared to metal alternatives.

- Consistent Quality & Repeatability – Ensures uniformity across large production volumes.

Here at SPR Takahata we place a strong focus on consistent quality and repeatability with world-class manufacturing.

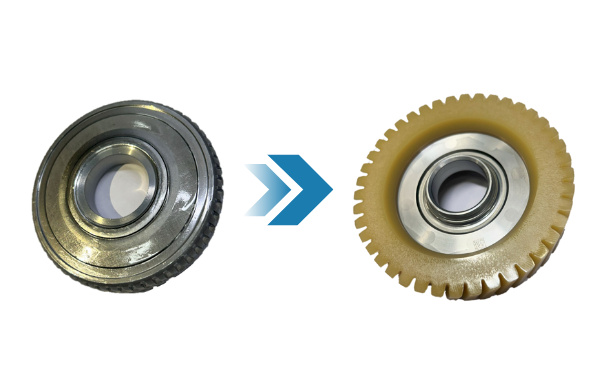

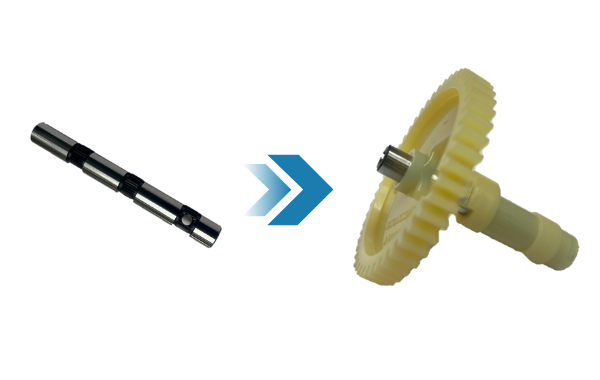

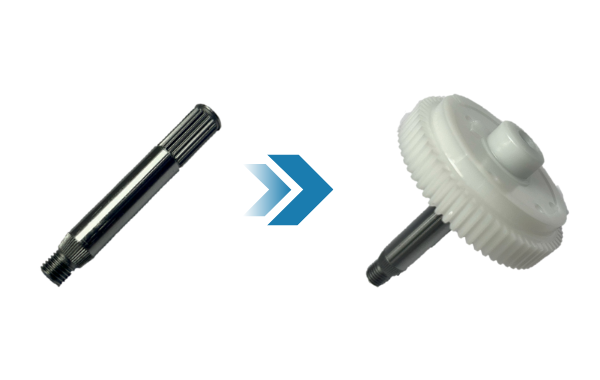

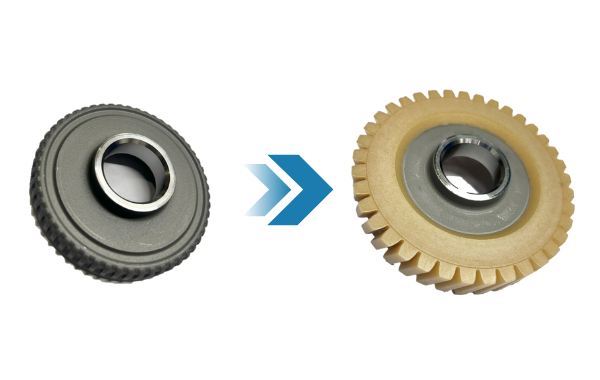

Precised Insert Moulding

We specialize in converting metallic parts into high-performance insert moulding plastic components, enhancing durability, reducing weight, and improving cost efficiency.

- Lightweight & High-Strength Plastics – Reducing vehicle weight for better fuel efficiency

- Precision Engineering – Ensuring seamless replacement without compromising performance

- Cost-Effective Solutions – Lower production costs with enhanced durability

- Custom Designs & Prototyping – Tailored solutions for automotive applications

Upgrade to advanced plastic parts without compromising strength or functionality.