OUR COMMITMENT TO QUALITY

Quality is the cornerstone of everything we produce. At SPR Takahata, we are unwavering in our commitment to delivering parts and components that meet the highest standards of precision, reliability, and durability. This commitment is upheld through a rigorous, end-to-end inspection process—starting with raw material evaluation and continuing through to final product verification.

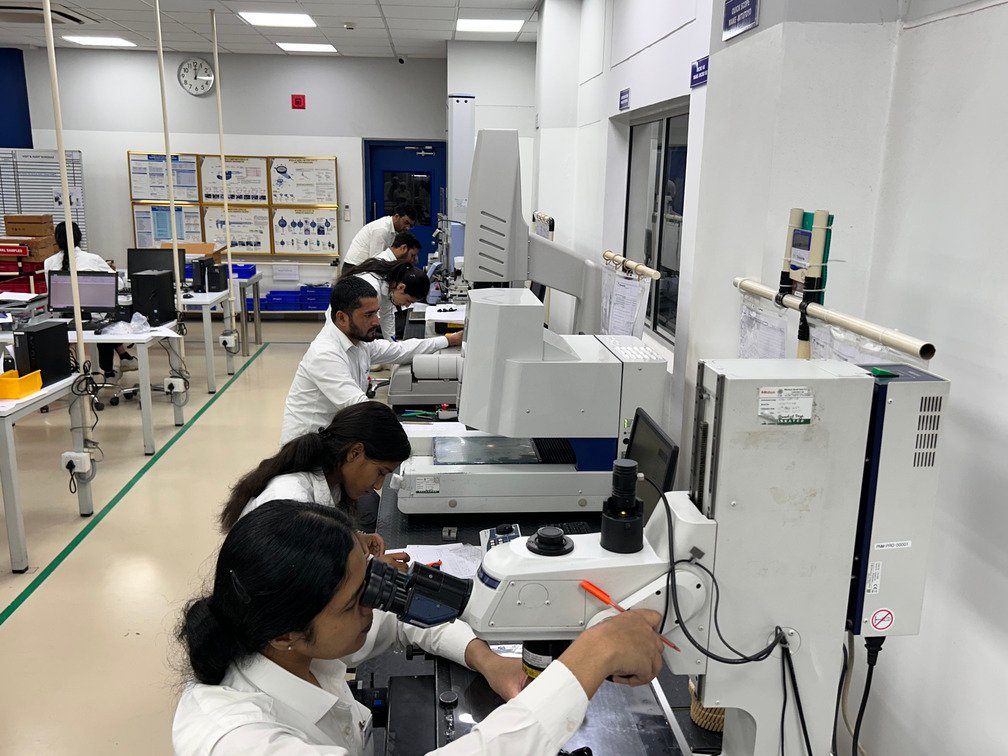

Our dedicated quality control team operates within a fully equipped, state-of-the-art inspection facility. Every product undergoes meticulous testing and analysis using advanced measurement systems and inspection tools capable of detecting even the slightest deviations. We ensure that every item we manufacture not only meets customer specifications but is also fully prepared for seamless integration into original equipment and high-performance systems.

Our Inspection Capabilities Include:

- Roundness Tester: Precisely evaluates the roundness of components and rotating parts.

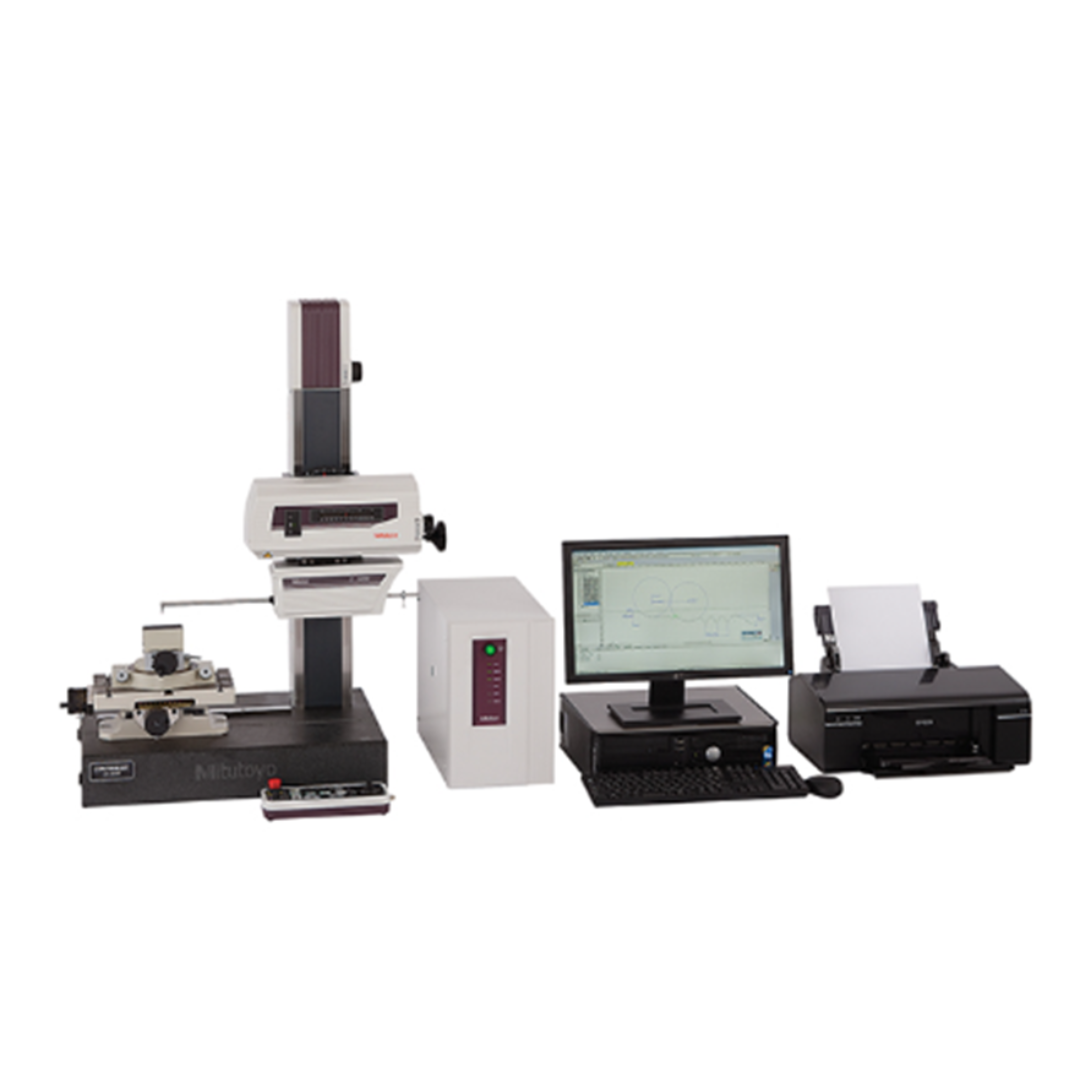

- Contour Tester: Accurately measures profiles, angles, and surface geometries to exact specifications.

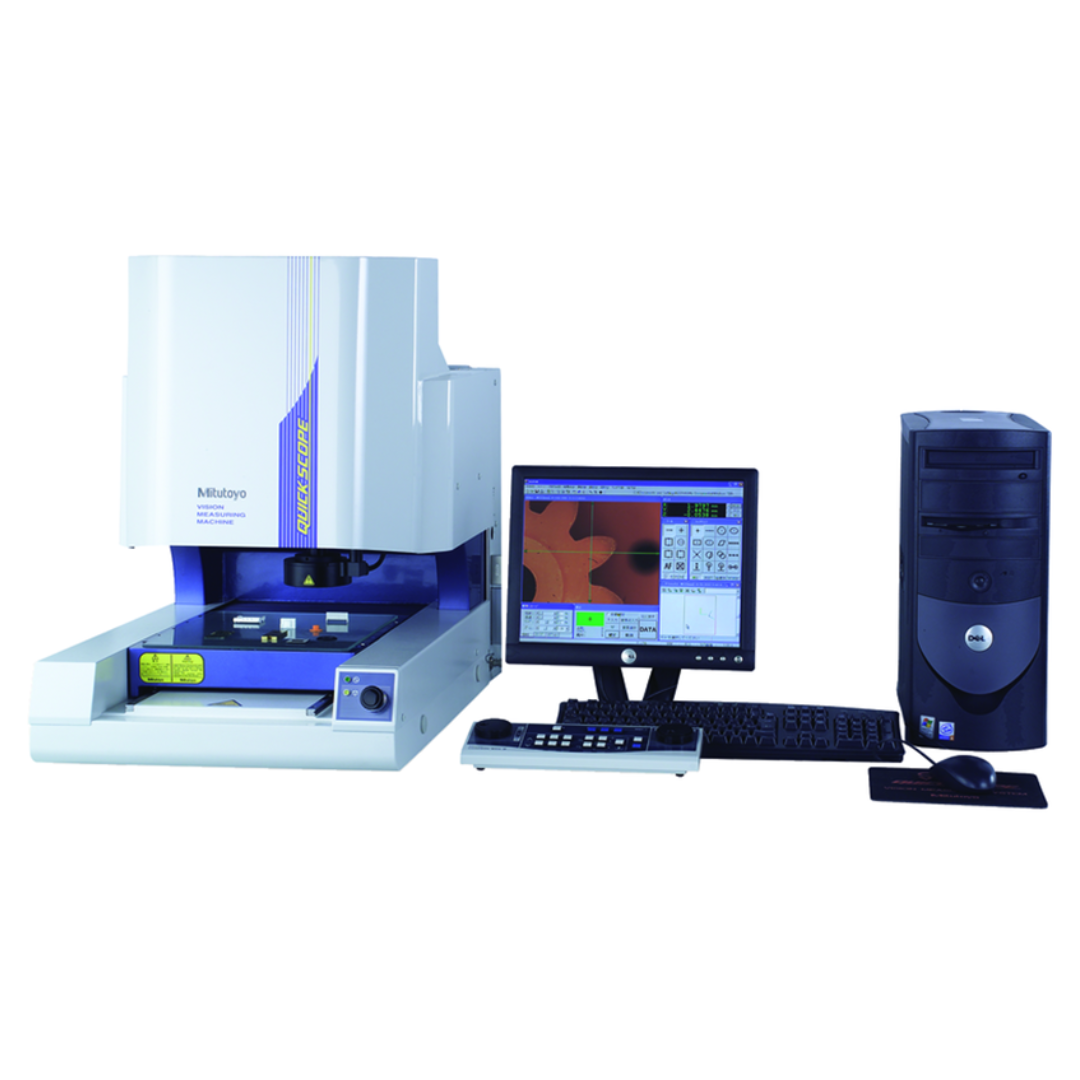

- CNC Vision Measuring System: Offers fast, non-contact measurements with micron-level precision.

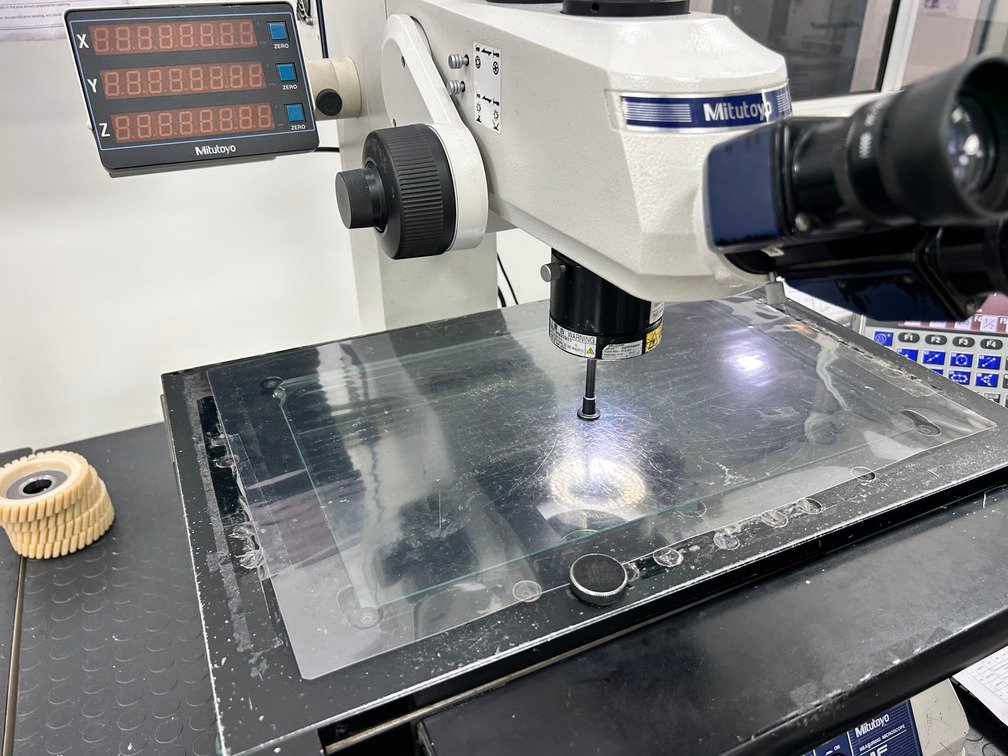

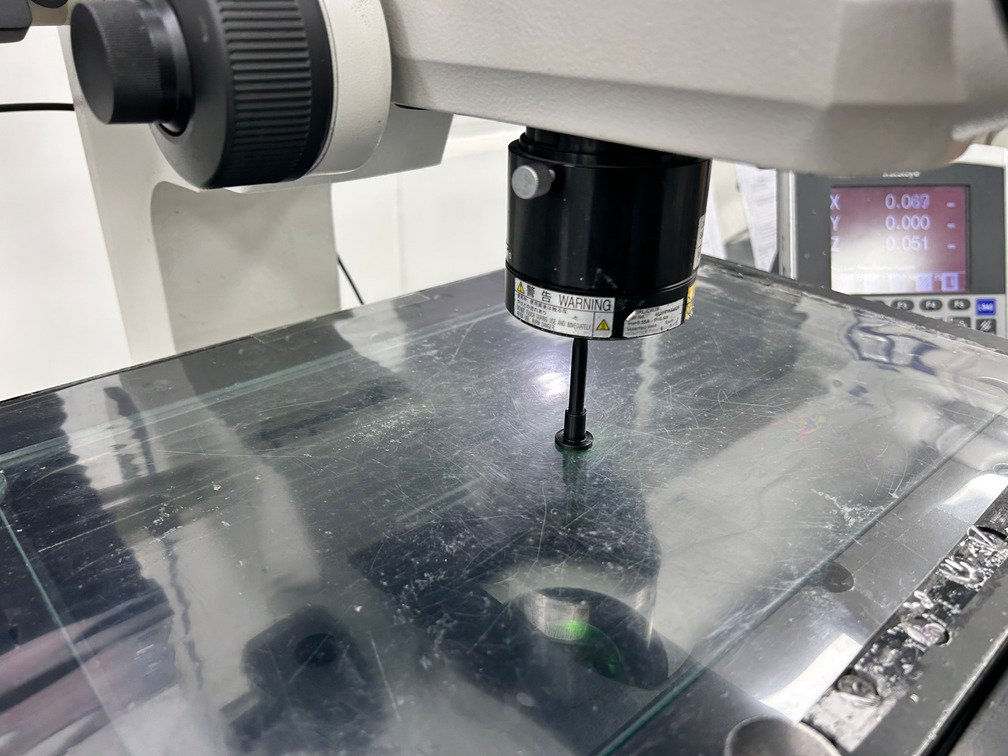

- Tool Measuring Microscope: Verifies dimensional accuracy and symmetry in cutting and forming tools.

- Micro VU Multi-Sensor Measuring System: Provides high-resolution, automated inspection for complex parts.

- Roughness Tester: Analyzes surface texture to ensure the required finish and functionality.

- CMM (Coordinate Measuring Machine): Delivers precise 3D dimensional inspection for intricate geometries and assemblies.

- Universal Testing Machine: Performs tensile, compressive, and bending tests to assess material strength.

- Hardness Tester: Measures material hardness to ensure durability, wear resistance, and long-term performance.

By combining skilled inspection professionals with advanced metrology equipment, we ensure consistent quality and strict adherence to international standards. Every part undergoes meticulous inspection—not only for physical attributes but also for functionality, fit, and finish—guaranteeing reliable performance in real-world applications.

At SPR Takahata Precision India Pvt. Ltd., quality is more than a checkpoint; it’s a deeply embedded culture. Our commitment to excellence is reflected in our investment in cutting-edge inspection technologies and robust quality assurance systems, ensuring every product meets the highest standards.